Micron Aerosols™

3608 - Protektor PolyCoat UV 5Ltrs

3608 - Protektor PolyCoat UV 5Ltrs

Share

Couldn't load pickup availability

Product Description

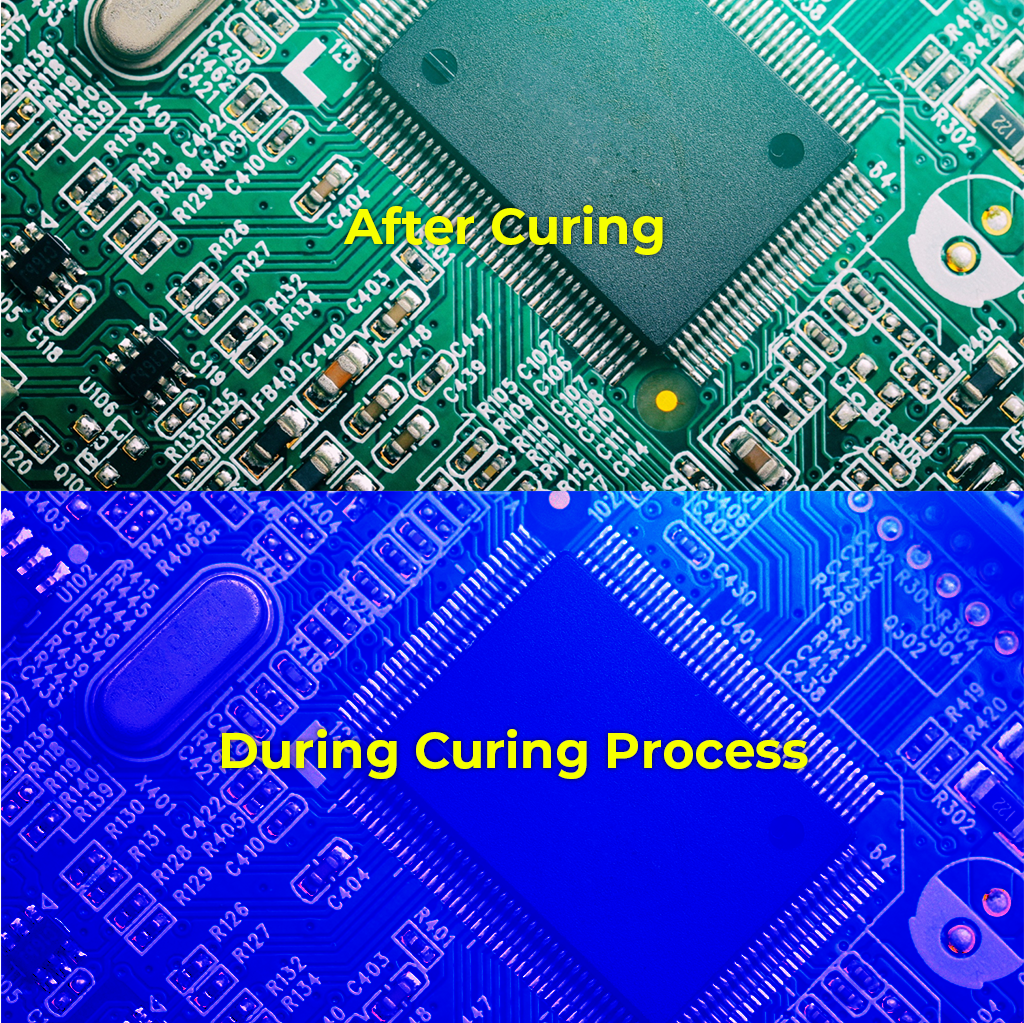

Protektor PolyCoat UV is a high-performance photopolymer resin coating specifically engineered to protect PCBs from corrosion, oxidation, and harsh environmental conditions. It forms a durable, transparent film with excellent adhesion, superior mechanical properties, and chemical resistance.

The coating cures instantly when exposed to a medium-pressure mercury vapor UV lamp, delivering rapid line speeds and high productivity. With a viscosity of 21 seconds (Zahn Cup #4 at 25°C) and density of 1.13 g/cm³, the formulation is optimized for spray, dip, or roller application in industrial settings.

Key Benefits

-

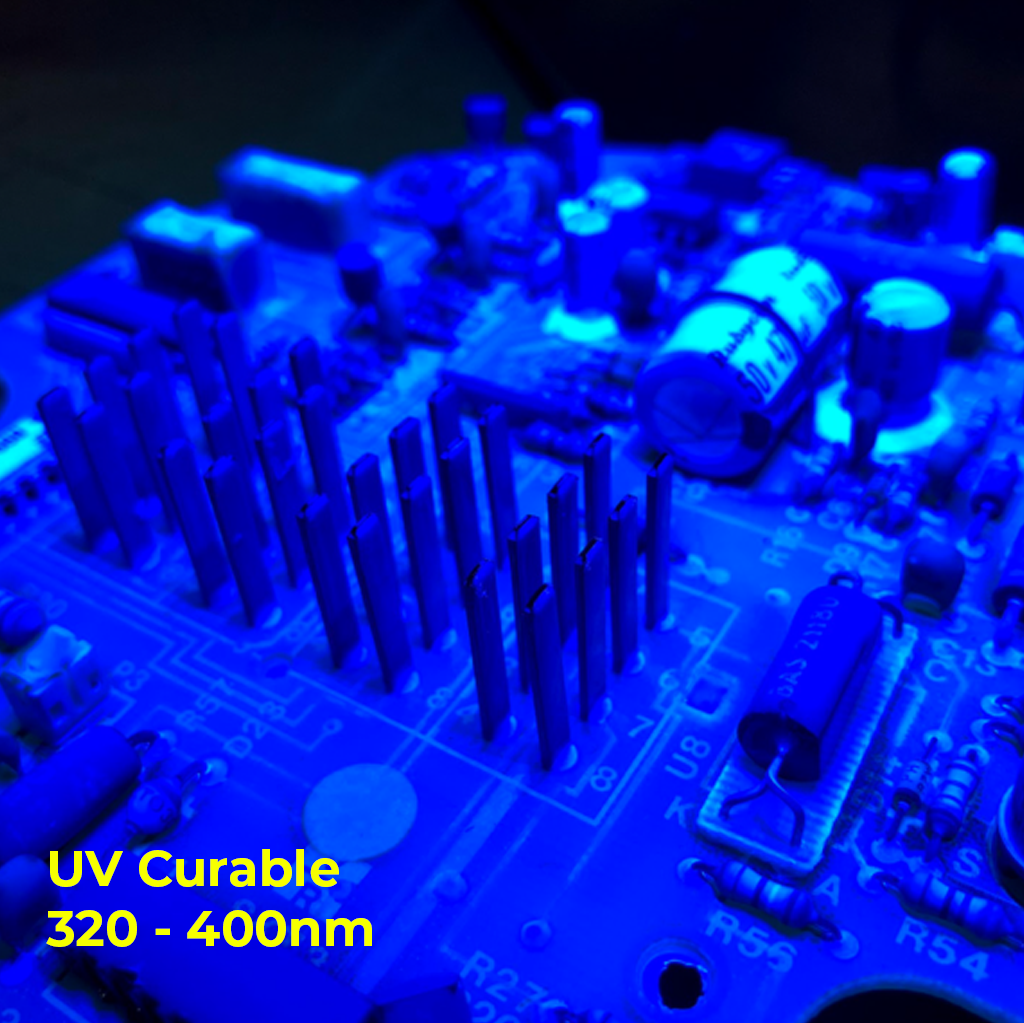

UV Curable: Rapid cure under UV light; improves throughput and reduces downtime.

-

Superior Adhesion: Passes Cross Hatch Test, ensuring excellent bond with metals.

-

Anti-Corrosion Protection: Provides long-term resistance to rust, oxidation, and moisture.

-

High Clarity: Dries clear and does not interfere with visual inspection of underlying parts.

-

Mechanical & Chemical Resistance: Withstands wear, abrasion, and chemical exposure.

-

VOC-Compliant & Solvent-Free: Reduced environmental impact and safer workplace use.

Applications

-

Protective coating for PCBs, metal tools, fixtures, sheet metals, and machined parts.

-

Ideal for use in automotive, aerospace, industrial machinery, and precision electronics.

-

Suitable for in-line UV cure systems or batch-curing environments.

Technical Specifications

| Property | Specification |

|---|---|

| Curing Method | UV – Medium Pressure Hg Vapor Lamp |

| Lamp Power | 300 W/in (Total 3 kW) |

| Curing Distance | 2 inches from lamp surface |

| Curing Speed | > 100 ft/min |

| Viscosity | 21 sec (Zahn Cup #4 @ 25°C) |

| Density | 1.13 g/cm³ |

| Appearance | Transparent, glossy film |

| Adhesion | Passes Cross Hatch Adhesion Test (ASTM D3359) |

| Film Hardness | Medium to Hard (Shore D scale) |

🧴 Directions for Use

-

Surface Preparation

-

Ensure metal surface is clean, dry, and free from oil, dust, or oxidation.

-

Use an appropriate degreaser or solvent wipe to prepare surface.

-

-

Application Methods

-

Spray, dip, or roll uniformly over the surface.

-

Recommended wet film thickness: 30–50 microns.

-

-

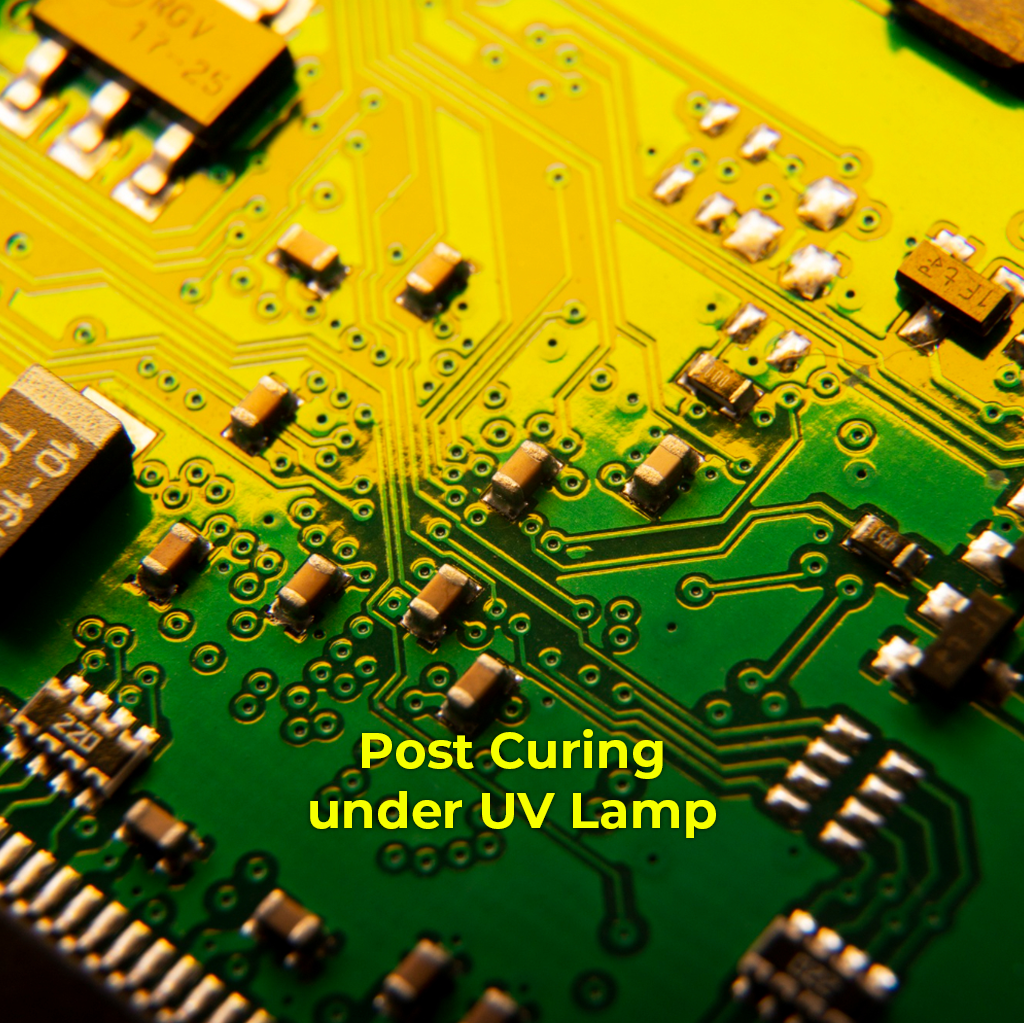

UV Curing Process

-

Use medium pressure mercury vapor lamp (300 W/in; 3 kW total power).

-

Maintain 2-inch curing distance from lamp surface.

-

Pass substrate under lamp at >100 ft/min for optimal results.

-

-

Post-Cure Handling

-

Cured surface is ready for handling immediately.

-

Full chemical resistance may develop within 24 hours.

-

Precautions

-

Store in a cool, dark, dry place away from sunlight and ignition sources.

-

Avoid skin or eye contact. Use appropriate PPE during application.

-

Do not use in confined spaces without adequate ventilation.

-

Ensure UV safety shields are in place to protect operators during curing.